This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

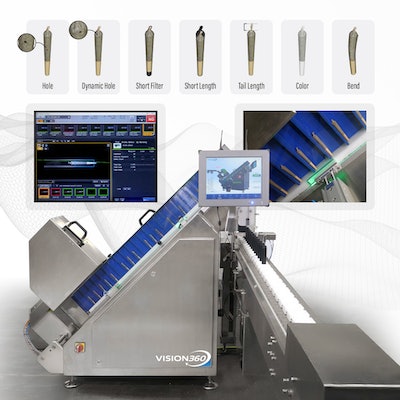

WeighPack Systems Inc. has launched the Vision360 Inspection System, which automatically inspects a pre-roll's filter, body, and twist for length, depth, cuts, tears, and any other irregularities.

Created to address critical quality control challenges faced by pre-rolls manufacturers, the Vision360 Inspection System enhances productivity, significantly reduces manual inspection time, and ensures consistently high-quality products.

Key features of the WeighPack Systems Inc. Vision360 Inspection System include:

- 360 Degree Vision: The technology captures a comprehensive view of every aspect of the pre-roll, inspecting the filter, body, and twist from all angles, minimizing the risk of undetected flaws.

- Automated Inspection: With its high-speed inspection capability, the Vision360 rapidly assesses multiple pre-rolls, enabling increased production efficiency while maintaining exceptional product integrity.

- Precise Analysis: The system's algorithms meticulously evaluate length, depth, cuts, tears, and other irregularities, providing accuracy and consistency.

- Customizable Settings: Every pre-roll manufacturer has unique requirements. The Vision360 is easily adjustable, allowing for tailored inspections based on specific quality standards or regulatory guidelines.

- Seamless Integration: Designed to integrate into existing production lines or in a manual process, the Vision360 can be easily incorporated without disrupting manufacturing operations, ensuring hassle-free implementation and minimizing downtime.