This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

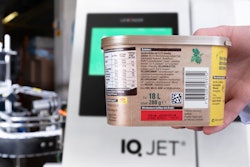

Videojet’s CIJ printers are designed to help increase throughput, minimize downtime, and reduce costs over the printer's life. The 1880 Series printers apply clear codes on a wide range of materials, including plastic, glass and metal, on high-speed production lines.

The Videojet 1880 + features built-in Wi-Fi and cellular connectivity to help users meet their current and future Industry 4.0 goals. It delivers seamless, non-contact industrial printing on almost any substrate, including flat and curved surfaces. The printer also enables proactive analytics and intelligent plant operations, such as vital sign monitoring, smart alerts, remote support, and advanced troubleshooting.

The Videojet 1880 UHS is an ideal solution for high-speed production lines in the canning, beverage, and wire and cable industries. With refined printed characters and an enhanced printhead, this ultra-high speed printer delivers consistent performance and print quality, even at speeds surpassing 500m/min.

The Videojet 1880 HR is engineered to consistently produce high-resolution micro-characters, QR codes, and other 2D codes with precision and clarity. It leverages optimized fonts and a redesigned printhead to deliver micro-printing for the electronics, pharmaceuticals, cosmetics, and confectionery industries while meeting the growing demand for product traceability.

The 1880 Series printers offer an improved user experience through a 10-in. SIMPLICiTY touchscreen interface that helps simplify operation and reduce user errors while offering intelligent message creation and built-in wizards. The integrated Videojet MAXIMiZE diagnostic toolset can proactively identify potential faults, while analyzing performance, operator behavior and environmental conditions to help reduce unplanned downtime and overall ownership costs.

The printers are equipped with a unique sensor that detects build-up in the printhead and proactively alerts users to potential print quality issues. With the auto-rinse feature, code clipping can be avoided as ink buildup can be cleaned with the touch of a button. Color-coded, easy-to-replace Videojet SmartCell components help simplify maintenance, requiring one annual five-minute replacement.