New at PACK EXPO International is Redzone's Frontline Learning Module, an addition to the company's workforce solutions software platform. Richard Tester, Redzone's co-founder and CEO, says the new module aims to take tribal knowledge about operating manufacturing equipment out of the heads of machine operators and onto Redzone's platform as video, where it can be watched as a best practice by other employees.

"If you've run a filling machine, for example, for 25 years, you know the best way to use it, or do the startup or changeover on it," Tester says. "With our new module and an iPad or iPhone, you can record a quick two- or three-minute video, which can become a best practice for that machine at your company. It's like a YouTube application for the plant floor. Like anything in life today, if we want to learn how to change a tire on a car, for example, we can go to YouTube and watch a five-minute video, right? So we're introducing that technology onto the plant floor, and it looks at the whole frontline employee experience, which we think is something that's been massively overlooked in manufacturing for the last couple of decades."

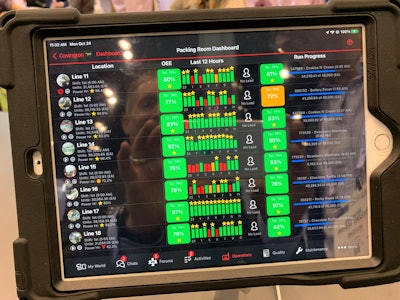

The Frontline Learning Module comes on the heels of Redzone's other recent addition, the Reliability Module, which puts basic machine maintenance knowledge into the hands of operators and tracks machine OEE and maintenance schedules, so maintenance crews can focus on crucial repairs, especially helpful for manufacturers with a labor shortage.

"The technology really drives all of the daily operating behavior for the frontline teams," Tester explains. "Whether it's running the line and tracking performance, whether it's quality, whether it's maintenance--this gives operators the ability to do basic preventative maintenance. So we shift maintenance resources away from performing day-to-day tasks, and move basic care for the equipment into the role of the operator."