Admiral Beverage Corp. is among the largest suppliers of carbonated soft drinks (CSD) in the western United States. Opening in Wyoming in 1947, it has grown to three large facilities supplying carbonated and still beverages, bottled water, and fountain mixes to multiple distributors throughout the mountain and western states and Alaska. As that growth continues in an ever-expanding marketplace, the company continuously seeks ways to increase its already significant productivity.

In 2017, Admiral contacted Bevcorp to explore updating the software in the 22-year-old, earlier model Micro blenders on its PET bottle and can filling lines. In the ensuing conversations, Bevcorp introduced Admiral management to the new MicrO2 blender it had developed and suggested that Admiral might be a valuable beta site for the new technology. The system limits dissolved Oxygen (DO) to reduce foaming, which in turn allows the line to run faster. Faster speeds result in more throughput and reduced costs per unit, as well as the correlating reduction in energy costs by not having to refrigerate ingredients.

“We immediately agreed,” says Dave Willard, Admiral’s vice president of production. “It was obvious that the new system they described could provide us with significantly higher productivity while simplifying production and reducing costs. Once it was installed, it was quickly confirmed that was the case, and two weeks later I called Bevcorp and told them I was budgeting for another MicrO2 system for our can filling line. Two weeks after that I called again and told them not to wait, but to build that second system immediately.”

Both lines have been operating continuously with the MicrO2 blenders ever since.

Design advantages

The MicrO2 design turns traditional blending/deaeration procedure on its head. Whereas traditional systems deaerate water prior to blending, MicrO2 deaerates the fully blended product prior to carbonation instead of only deaerating the water. Traditional methods introduce DO into the product mix in the syrup.

This difference enables the MicrO2 to deliver blended product to the filler with lower DO levels of 0.1 ppm for carbonated sugary soft drinks and 0.3 ppm for diet soft drinks. This compares to DO levels resulting from the traditional process of 1.8 ppm.

“The fact that the MicrO2 system integrates deaeration makes it not only more efficient, but also more precise,” points out Admiral’s plant manager Clarence Foster. “Air is driven out of the product by CO2 and nitrogen flushing rather than by pumps and valves, and is done right at the point of use rather than remotely.”

In addition, to reduce the possibility of air being reintroduced at the filler, during installation of the new system the Admiral and Micro Blend teams added a purge system to the Bevcorp filler that reduces air from entering the product at the filler.

Reducing DO and N2 levels improves the stability of a beverage during packaging, whether in cans or bottles. There is less foaming at the filler, which enables higher filling speeds. Beverages can also be filled at higher product temperatures. Traditional methods attempt to compensate for higher volatility by lowering temperature. The MicrO2 process reduces volatility by eliminating non-CO2 gasses, making lowering the temperature unnecessary. This then reduces refrigeration costs and improves control over net weight that increases yields. A lower DO level also lowers the volatility of the product, minimizing opportunities for gases to be reintroduced at the filler and producing greater CO2 consistency.

MicrO2 is also ideal for use with cans that feature new, first-generation BPA-NI (BPA non-intent) liners that are more susceptible to DO than BPA-lined cans. This is particularly important when using cans from can-makers that guarantee “no leakers” only for filled cans with DO levels less than 1.2 ppm.

Perhaps most significant for the customer and retailers, lower DO levels contribute to maintaining product flavor longer through the beverage’s shelf life, and can also extend that shelf life itself.

For Admiral, the payback period for the cost of installing each new system is about 1.8 years. In addition, because the new line configuration lowers power needs for the facility significantly, Rocky Mountain Power, the local power utility, provided incentives that reduced the cost of power even further. For example, the power required for refrigeration on the previous bottle and can lines totaled 500 HP; today both lines use 25% of that amount of power. On average, product temperatures at the lines’ filling heads went from 33°F to 46°F; some of the products being filled require no refrigeration at all.

This was one of the surprises,” says Willard. “I didn’t believe we could fill at those higher temperatures. But they proved me wrong.”

Willard also points out that installing any new technology usually comes with some “hiccups.”

“But hiccups are acceptable as long as people are available to deal with them. Bevcorp’s technicians were onsite during the early period, and challenges that came up were solved very quickly. Since then, they have always been only a phone call away.”

Eliminating offline deaeration

The traditional blending system previously used by Admiral included a remote deaeration system that treated water prior to blending. This deaerated water was then piped several hundred yards to the first-generation Micro Blend blender where it was blended with syrup that included naturally occurring levels of DO. The result was high levels of DO at the filler. Admiral had found in the past that, even when it began deaerating the syrup prior to blending, that only partially solved the problem, since the resulting blended product was highly volatile and tended to pick up more oxygen during the filling process.

Using the same filler, MicrO2 lets Admiral increase filling speeds of its 2-liter bottles by 25%.

Using the same filler, MicrO2 lets Admiral increase filling speeds of its 2-liter bottles by 25%.

By adopting the new MicrO2 system, with its post-blending deaeration, Admiral not only achieved overall lower DO levels in its beverage products, but was able to eliminate its remote deaeration system completely, with its aging tanks, valves, vacuum pumps and associated lengthy piping (leaks in which had tended to allow air to enter and partially re-oxygenate the water). The MicrO2 system, in addition to eliminating that piping, occupies a smaller footprint on the production line, and incorporates fewer wear parts to be cleaned and maintained.

“We are not your usual beverage company,” says Willard. “Our production and maintenance teams are highly skilled and have years of experience, so we were able to install the new MicrO2 system ourselves, in a minimum amount of time.”

Bevcorp had estimated it would take 7 to 10 days to remove the existing blending and carbonation tanks and other equipment and install the new system; Admiral’s staff completed the task and had the line up and running in 4 days.

“If the previous system had been from another manufacturer the installation might have been more involved,” says Foster. “But Micro Blend’s systems are self-contained, so our main task was to remove the skids holding the previous Micro Blend blender and carbonator, and move in the MicrO2 system.”

Other installation tasks included making software adjustments to enable the new and older line components to work smoothly together and piping connections between MicrO2 and line components and gas supplies.

Higher filling speeds and changeovers

Lower product foaming at the filler is what enables filling to take place more quickly. Admiral’s 60-valve bottle filler from Bevcorp was filling 2-liter bottles in the past at 165 bottles per minute; today the filling rate is 210–a better than 25% increase. It was filling 20-ounce higher-carbonated drinks at 400 bottles per minute; that speed today is in the 460s, a better than 15% increase.

In addition to higher filling speeds, the MicrO2 system increases productivity by its operational simplicity.

“Every beverage is different,” points out Foster. “The previous system required operators to make adjustments as each new product recipe was bottled. Today, most of those adjustments are made by the software in the MicrO2, and operator involvement is minimal.”

Admiral is also unique in that is blows its own PET bottles from preforms to supply the filling operation--the company employs injection stretch blow molding machines including a SIG Corpoplast Blomax and KHS InnoPET Blomax. The speed of the blowing operation, as well as the capacity of the current filler [*capacity recently increased], are the major limiting factors to even higher productivity.

Another factor that can affect productivity in a beverage filling operation is product changeovers. Production comes to a halt while fillers are drained and cleaned, blending tanks drained and new product brought in, etc.

The MicrO2 system speeds Admiral’s product changeovers by compressing that time: a critical innovation in the MicrO2 system is that the filler is being washed down as the blending tanks upstream are simultaneously being filled with the next product.

Downstream adjustments

Higher filling speeds are the major benefit of having installed the MicrO2 system, enabling Admiral to immediately increase productivity without the need to add a new, larger filling system. But at the same time, higher fillings speeds can also put pressure on downstream equipment–including both case packing and palletizing operations–to keep up with the new higher speeds.

Currently, the existing bottle line case packing conveyor and packer and the downstream stretch wrapper are handling the speed increases with no problem. The can line already had excess capacity downstream and was able to expand to meet new speeds.

“Eventually,” says Willard, “our plan is to install a larger bottle filler* with more heads, and that will mean beefing up the downstream case packing and stretch wrapping as well.”

[*Editor’s note: this installation was indeed completed, in the form of a new 96-valve Bevcorp filler, around the time of publication in fall 2019. The the 60-valve filler in Pleasant View, Utah will be sent to Admiral’s Nampa, Idaho facility, where the next MicrO2 blender is scheduled to be installed.]

The full PET bottle packaging line

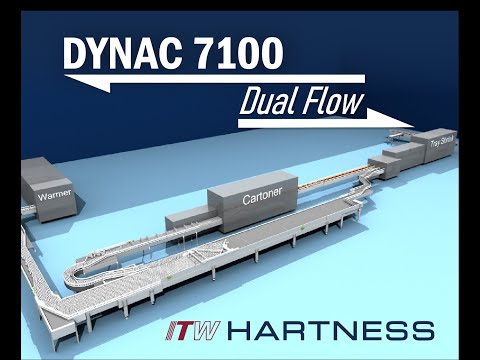

As mentioned above, the bottles for the PET line are blow molded in-house. The company’s blow molders come from KHS & SIG. An air conveyor from AMT carries the freshly blow-molded empty bottles into a Sidel labeler (labeling is done on the empty bottle side of the facility) before the bottles enter the new Bevcorp 96-valve filler (*previously was a 60-valve filler) with 24-head CSI capper. Full bottles are handled on an Alliance Industrial Corp. conveyor to be bundled on an ITW Hi-Cone bundler/packer. An ITW Hartness Model 2600 is used for case packing, and a Douglas Model SPS60 is used for packing and shrink-wrapping trays. Full case conveyance including a spiral case incline are both accomplished by Alliance Industrial Corp. material handling, and the end-of-line features a stretch-wrapper from Orion, a ProMach brand.

How it turned out

“The results are all positive,” says Willard. “The quality of the product is better because the CO2 content is consistent and balanced; the speed of production is increased because the speed of the filler is not restricted by foaming; the overall cost of production is significantly reduced because the system is simpler; and the ROI is accelerated.”

From the very first weeks the MicrO2 system was in operation on Admiral’s PET bottle line, it has proved itself. Today, the plan is to eventually introduce it into Admiral’s entire bottle and can filling lines across all of its other facilities in Wyoming and Idaho.

The immediate result is that Admiral Beverage can continue its pattern of steady growth and its ability to reach new customers without the need for costly investment in additional production lines. That saving is itself another benefit.