This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

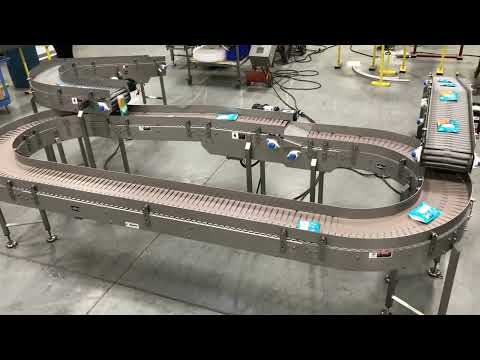

For one project, the customer requested to divert the product to the left or to the right on command for stacking purposes.

Multi-Conveyor engineers designed a 5-sweep pop-up powered divert, using individual motors and controls, to pull a gap and divert to the operator-set direction. The diverter control parameters are manually set by product size. A photo-eye on the discharge of the conveyor triggers the sweep lift cylinders, diverting products to the appropriate side.

An operator will select the appropriate length and left/right direction using manual switches located on the main enclosure door. The product now diverts to the opposite side.

In the second project, Multi-Conveyor built a multi-strand indexer, to move heavy cartons of stacked elongated metal product, up to 560 lb total weight at any given time, across 12 ft of conveyor chains. Due to the product width, the system has a common shaft configurations for 8 narrow chains instead of one extremely wide and costly belt conveyor. See this equipment in action. (Note: Product in these videos were used for demonstration purposes only.)