This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

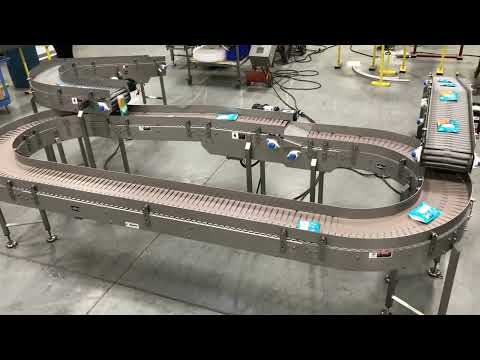

Multi-Conveyor provided the C-grippers for a CPG manufacturer that transports from cartoner exit, through C-grippers to stage at heights needed to feed batch case packing or manual hand-packing ahead.

Nick P., Engineering Manager, explains, “We love using the C-Gripper for the small footprint that it has to get our cartons out of the way for more floor space.” The gripper elevation also provides maximum operator walk through area below.

A manual hand crank easily adjusts compression for changeover product widths that can be tracked by the simplistic digital readout. Grippers typically facilitate product rotation for case packing, coding or labeling upstream.

According to Randy L., Process Engineer, “When the carton leaves our cartoner they’re upside down. The C-Gripper allows us to orientate the carton in the right direction, right-side up.” This is required for the case packing ahead.

Bypass conveyor sections can be provided when product orientation or elevation is not required. A simple toggle switch allows the operator to easily choose “bypass” or “engage gripper” on command. Locking casters are commonly added for portability and easy maintenance. Watch the video to see the system in action.