This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

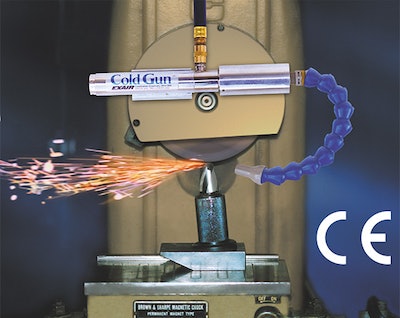

EXAIR's Cold Gun Aircoolant System produces a cold, quiet stream of air to reduce heat buildup on machining operations and has met the rigorous safety, health, and environmental standards of the European Union in order to attain the CE mark.

The Cold Gun is a low-cost alternative to expensive mist systems. It eliminates the ongoing costs associated with the purchase, filtration, and disposal of liquid coolants. In addition, there are no worker-related health problems resulting from breathing airborne coolants or slipping on wet shop floors.

The Cold Gun Aircoolant System incorporates a stainless steel vortex tube to convert an ordinary supply of compressed air into a cold 54°F (30°C) air stream at one end and a hot exhaust at the other. There are no moving parts to wear out. The Cold Gun now features an improved muffler on the hot air exhaust to reduce the noise level to a quiet 70 dBA. A flexible ball and socket hose that holds its position is used to direct the cold air to the point of use. A magnetic base provides easy mounting and portability.

The Cold Gun Aircoolant System is non-adjustable to prevent freeze-up during continuous use. It is ideal for machining applications that include tool sharpening, drill and cutter grinding, milling, drilling, surface grinding, band sawing, plastic machining, plunge and form grinding.