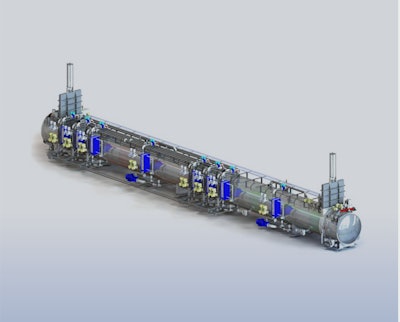

Surdry, a second generation, family-owned autoclave manufacturer for the food and beverage industry, introduced its continuous sterilizer in North America at PACK EXPO Las Vegas 2023. The equipment is designed to provide manufacturers with increased flexibility in running a wide range of primary packaging – from cups and pouches to non-round containers and traditional round or square cans.

The continuous sterilizer is an inline solution meant to ensure better quality with its capacity to sterilize over 800 pouches per minute, or half a ton of product every five minutes. The sterilizer is typically run at temperatures of 250 degrees Fahrenheit +/- 30 psi to prevent the packages from swelling during the high temperature base. This results in better quality and more reliable sterilization, according to Jose Bertomeu, owner of Surdry Spain.

Machine features include:

- Easy access to maintenance teams with its horizontal design,

- Clean-in-place,

- Predictive maintenance,

- Adjustable length and diameter of the equipment to meet slower speeds for medium-sized companies.

- Two separate HMIs, designed for ease-of-use, to control heating and cooling and for the handling system and automatic changeover.

Depending on the complexity of the transition, changeovers can take as little as 10 minutes or up to three or four hours. Mechanical adjustments to infeed and outfeed, recipe changes, and the use of robotic systems contribute to the changeover timeline. The system can also be customized to maximize a manufacturer’s production and minimize changeover duration and downtime.

| unPACKed podcast: Must See Technology and Trends |

Sustainability benefits

The continuous sterilizer’s defining features is its adaptability. Manufacturers aren’t tied to a single container type. Whether it's pouches in the morning and cans in the afternoon, the continuous sterilizer seamlessly switches between different packaging materials, says Bertomeu. This flexibility opens up new avenues for food manufacturers to diversify their product offerings and adapt to evolving market trends as well as choose the materials that best suit their environmental objectives.

In comparison to batch retort systems, the continuous sterilizer saves 30 to 40 % energy by maintaining its temperatures in the heating and cooling zones. Though the equipment can be turned off and on daily and be fully operational within an hour, it saves more energy being kept on for extended periods of time and run more consistently.

The equipment is also designed to minimize waste and be increasingly reliable by reducing the number of potential failures that end in product waste.