This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Allpax will customizes this suite of applications to each customer’s specifications. Customization lowers the learning curve for customers and provides the utmost in capabilities for the customer’s environment.

This next generation suite of software solutions provides a new, higher level of functionality and flexibility, ease of use, security, and operational control versus its previous software suite, and is fully compliant with FDA regulations, including 21 CFR Part 11. Allpax software engineers invested over two years in the development effort. Allpax collaborated with outside process authorities and manufacturing leaders during the development process to ensure conformance to best industry practices for shelf-stable food sterilization safety, quality, consistency, and throughput.

Allpax developed the suite in the Microsoft .NET Framework. Placing the new applications within the Microsoft .NET environment ensures longevity and ease of both upgrade and future customization. The new suite also implements OPC UA for PLC-level communication, which enables the use of encrypted connections and enhances the security of machine data and interoperability.

Older Allpax retorts can be retrofitted with the new software suite, and Allpax also expects there will be demand for software retrofits on non-Allpax made retorts due to the ease of use and advanced capabilities. A substantial number of competitive retorts are already being retrofitted with Allpax software annually. The owners of these retorts say their existing software and/or hardware is obsolete and is too difficult or too inflexible to use anymore.

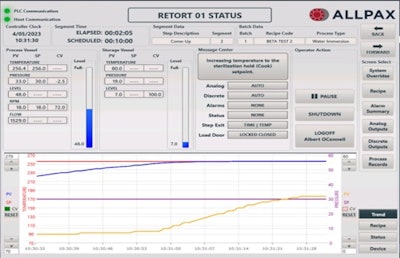

The AllSet supervisory control software allows customers to designate authorized users, and to create and edit recipes. AllSet users can review batch process data in both tabular and graphical formats. The application generates reports that enable users to review system efficiency, as well as assess processes for accuracy and validation.

The AllLog logging engine captures process data while ensuring tamper-resistance. AllLog records data onto the customer’s designated server or onto an Allpax provided server. AllLog automatically begins capturing data as soon as a process begins and autonomously operates in the background during operations without operator input.

The AllView application controls and interfaces with the retort and automated batch retort system. It was designed to adhere to ISA101 – the international standard for human-machine interface design. Users will discover that interactions with the interface feel completely modern and in line with current smart phone and computer interfaces. The interface makes it easy to spot operational anomalies, which promotes fast and effective responses. Although the interface has been refreshed and redesigned, layouts and core functionality were kept in place to minimize the need for re-training operators.